“Unveiling the Masterful Artistry: The Intricate Journey of Faucet Production”

When it comes to crafting the perfect faucet, an intricate production process unfolds, resulting in a masterpiece that effortlessly enhances your bathroom decor. From meticulously selecting the finest materials to embracing advanced technologies, every step is a testament to the pursuit of perfection. Join us on a captivating journey as we unravel the step-by-step process behind creating a faucet that exudes everlasting elegance.

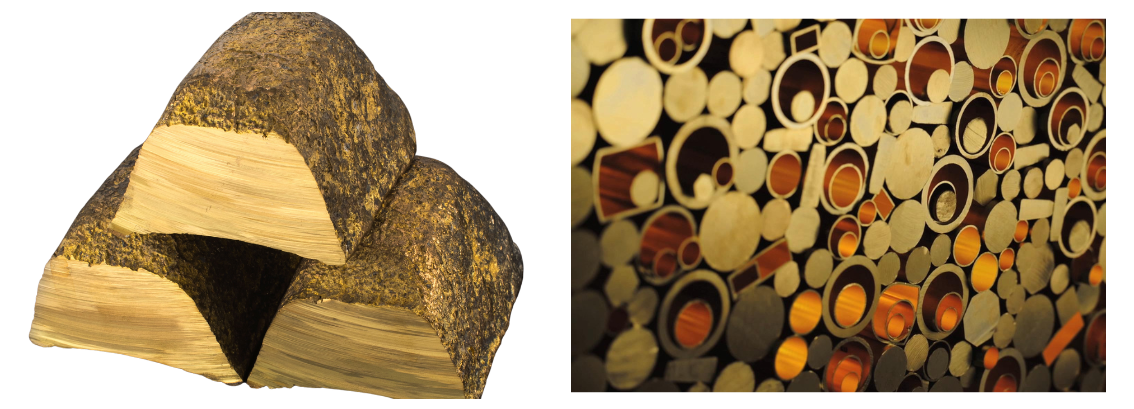

Step 1: Brass Ingot – Laying the Foundation

At the heart of every Aquilo faucet lies the selection of high-standard brass, ensuring durability and longevity. The raw materials are carefully chosen, setting the stage for a product that withstands the test of time.

Step 2: Sand Core – Precision at Its Core

Step 2: Sand Core – Precision at Its Core

Utilizing a cutting-edge sand core manufacturing process, our faucets boast impeccable internal structures. This attention to detail guarantees stable operation and an extended lifespan, delivering a faucet that exceeds expectations.

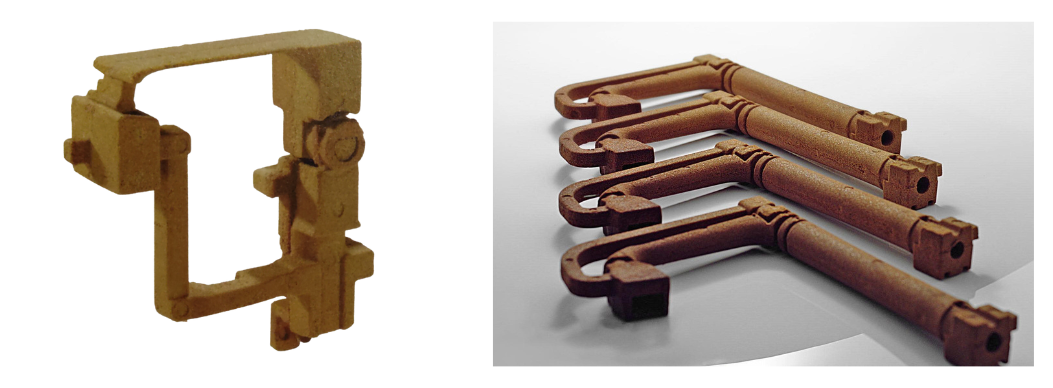

Step 3: Casting – The Art of Perfection

Optimizing casting parameters such as speed, pressure, and direction elevates the accuracy and uniformity of our castings. Through this meticulous approach, we offer products of superior quality and performance, leaving no room for compromise.

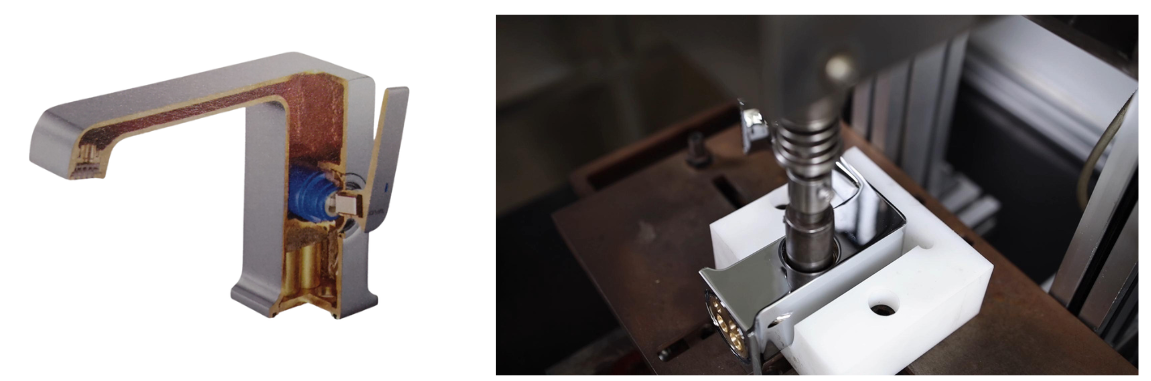

Step 4: Machining – Precision Redefined

Aquilo employs advanced CNC machining, enabling multiple processes to be completed seamlessly. This ensures accurate alignment and a flawless user experience, setting our faucets apart with their perfect fit and functionality.

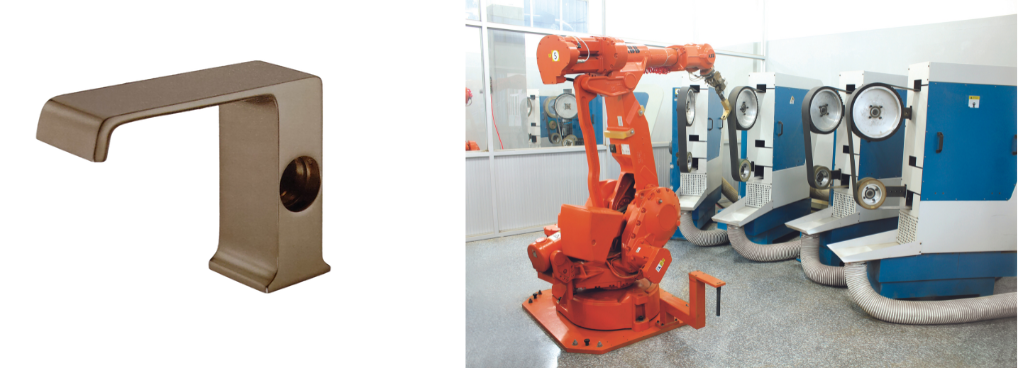

Step 5: Polishing – Reflecting Timeless Brilliance

Combining the finesse of intelligent robotic polishing with the craftsmanship of human touch, Aquilo achieves a flawless mirror finish. Our meticulous polishing process leaves no imperfections, creating truly stunning products that radiate timeless brilliance.

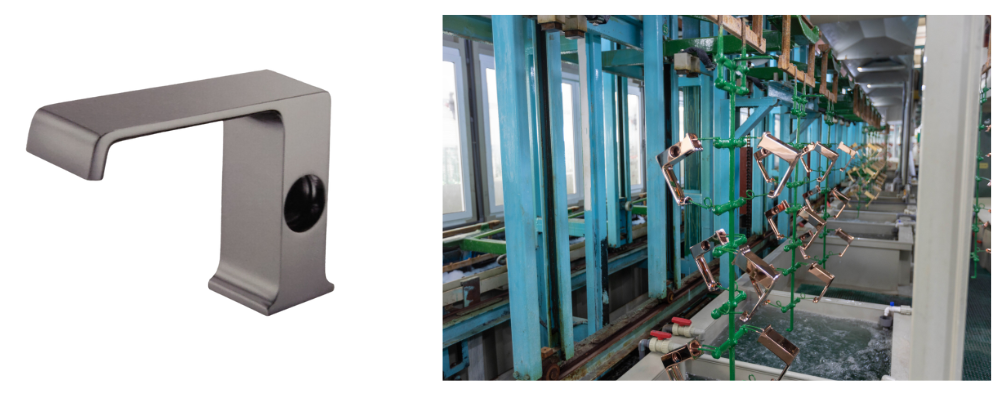

Step 6: Plating – An Enduring Glow

Through an automatic electroplating line, each faucet receives a durable finish, enhancing its resistance to oxidation and wear. This added layer of protection ensures that your faucet remains radiant and stunning for years to come.

Step 7: Assembly – The Seal of Excellence

At Aquilo, we leave no stone unturned in our commitment to quality. A comprehensive quality control system encompasses raw material inspection, process inspection, and finished product inspection. This meticulous approach guarantees that each Aquilo faucet surpasses expectations and delivers a mark of excellence.

The process behind faucet production is a harmonious blend of artistry, innovation, and unwavering attention to detail. From the selection of raw materials to the final assembly, every step is executed with precision and craftsmanship. The result is a faucet that not only meets rigorous standards but also adds an everlasting touch of elegance to your bathroom. Discover the Aquilo difference, where passion and dedication culminate in extraordinary faucets that redefine luxury and functionality.